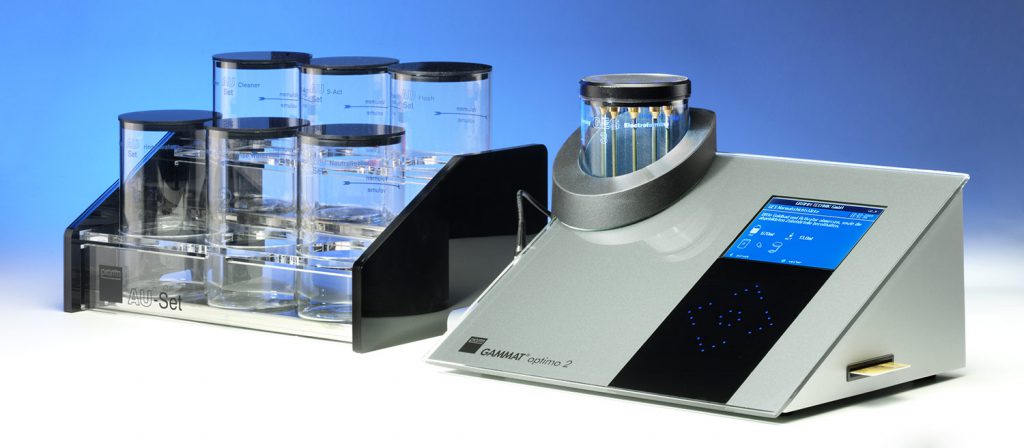

One for all… electroforming,

hard gold plating, and friction renewal

With the GAMMAT® optimo2, Gramm relies on the classical, well-tried advantages of the electroforming technique and combines this with state-of-the-art unit technology. Thus, one compact unit is sufficient to cover all electroforming indications and hard gold plating cases of model casting frameworks and friction renewal of worn telescopic dentures, tapered crowns and bar-retained restorations out of non-precious or high-noble alloys – with the advantage to adjust the layer thickness. This unit distinguishes by its easy operation via menu-guided display indications and an extremely high process safety. Thus, the user is offered utmost benefit at low investment and operating costs.

- electroforms up to 13 items at the same time

- runs 5 hours max.

- power reception: 200 W

- initialized via chip card providing easy software updates

- fully automated process run

- complete review of all parameters prior to process start

- illuminated plating head with LED loading indication

- optiCLIC contacting system

- automatic power reduction in case of improper contacts

- extremely easy operation

- visualization with graphics on the colour display

- automatic calculation of the gold amount

- choice of the layer thickness

- revolutionary hydrodynamics for improved uniformity of the deposits, even in case of difficult shapes

- wide range of indication

- high material output

- recycling process

- control in case of power failure

- interface for PC to print a process protocol

- compact dimensions

- high economic efficiency

- very low power consumption

- friction renewal of worn telescopic cases

- nickel-free 24K hard gold plating

- WEEE Reg.Nr. 8587809